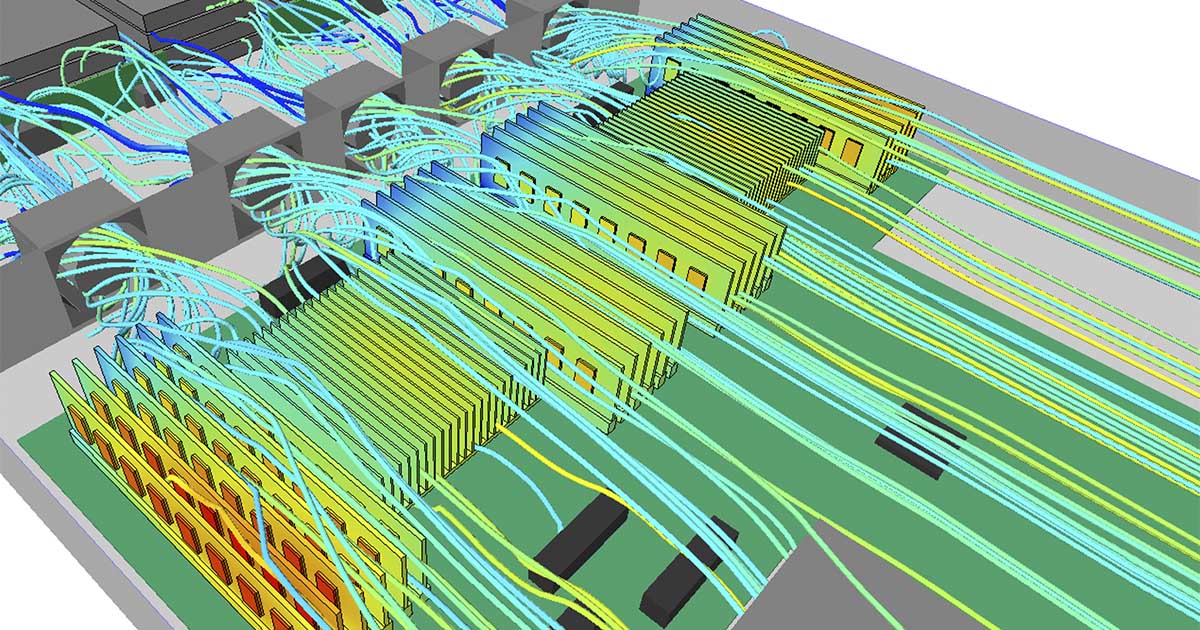

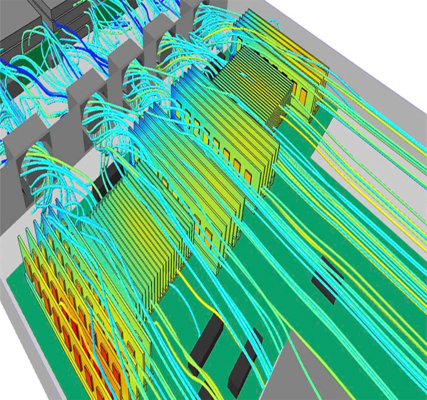

SIMCENTER FLOTHERM

Simcenter Flotherm is the leading electronics cooling simulation software for accurate, fast thermal analysis and supports the development of a thermal digital twin. It provides pre-CAD concept design space exploration, increasing analysis fidelity during development by incorporating ECAD and MCAD data, to final design verification. With over 32 years of user feedback-driven development, Simcenter Flotherm provides thermal simulation at the component, IC package, PCB, and enclosure levels, to large systems including data centers. Engineers can predict junction temperature, understand airflow and heat transfer to avoid risks of costly design re-spins. Leveraging optimization, and capabilities such as calibration to Simcenter T3STER thermal measurement, you can achieve the best thermal design for reliability faster.